Spring Operated reeling Drums | Motorised Operated reeling Drums | Flat and Pendant Flexible Cables

Round Power and Control Flexible Cables | Slipring Units and Collector Columns

Carbon Brushes and Brush Holders | Pendant Push Button Units | Cable and Hose Drag Chains

Busbar Systems | Plugway Plug in Power Duct | Radio Controlled Systems

Crane Load indicator | Load Limiter | Multipole Connectors | Surplus Stock

Contact Nova Electrical

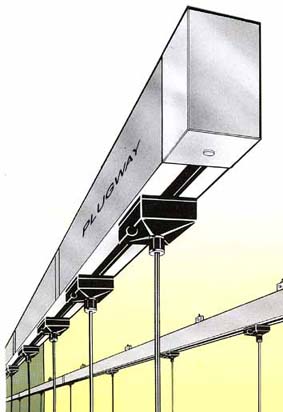

Plugway plug-in busbar system for textile sewing machines |

||

|---|---|---|

Standard Length of Plugway Busbar Trunking |

Plugway plug in ducting system has been especially designed for feeding single phase sewing machines, 3 phase sewing machines in the clothing industry, also portable appliances, general lighting, machine lighting, small motors up to 3hp (415v.3 phase), assembly benches, test benches and cleaning equipment. |

General Arrangement of Plugway Busbar Trunking |

|

Standard Plugway Busbar Trunking Plug |

Plugway Busbar Trunking Tap-Off PlugsEach plug unit is provided with a fuse compartment and individual cartridge fuses (5,10 or15amp), assess to the fuse compartment is only possible when the plug has been removed from the busbar trunking.

|

Standard Plugway Busbar Trunking Plug showing fuses |

Inserting plug into Plugway Power Duct |

So simple and safe to connect or disconnect machines to Plugway power duct |

Click here for :-

|

|

POWER TRACK for CUTTING TABLES |

||